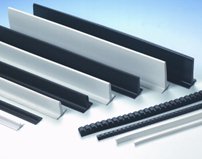

Hose/Conveyors, Inc. has a full capacity belt fabrication shop for

both Rubber and Thermo-plastic belting. Capable of the widest range of cleat

arrangements for your belting needs.

Have a specialty rubber cleat application? Hose/Conveyors, Inc. builds all of

its own rubber fabrication dies in-house and can accomplish any cleat size and

profile arrangement. Contact us to discuss your special needs.

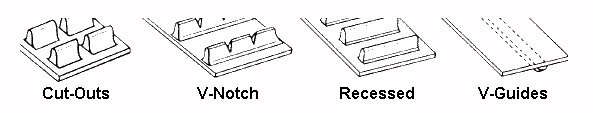

Notching & Cut Outs

Cleat Notching and cut outs. Hose/Conveyors, Inc. complete fabrication

capabilities include cut-outs, V-Notch, recessed, and notched v-guides as part

of the primary or secondary fabrication process.

Step Splice:

Step Splice: Used on belts with multiple plies.

The belts can be vulcanized hot or cold using uncured rubber, thermoplastic or

glues as the bonding agent. The splice is almost as strong as the original belt.

Single Finger Splice: This splice is used on

thermoplastic belting with single or multi plies. The cover material when vulcanized

will re-melt into itself and produce a smooth, strong and almost unnoticeable splice.

This endlessing process is done under heat using a pressurized vulcanizing press.

Finger over Finger Splice: This splice is used

on multi plied thermoplastic belts where additional strength or small diameter

pulleys are used in the application. This endlessing process is done under heat

using a pressurized vulcanizing press.

Skive Splice: This splice is normally used on

nylon core power transmission, process belts, machine tape belts and some

thermoplastic belts. This splice is also done under heat with a pressurized

vulcanizing press.

Hose/Conveyors, Inc. is proud to carry the full line of Flexco Products.

More details on our fasteners can be found Here!

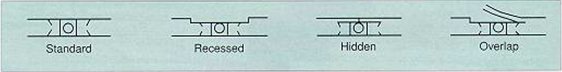

Below are the different ways to incorporate fasteners into a belt:

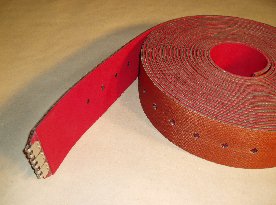

All our belts can be hole punched to your specifications.

This is done to attach elevator buckets or special conveyor

attachments in a secondary fabrication process. Hose/Conveyors, Inc.

assures accurate hole punching by using a die cutting

machine or precision machined templates by having this operation

in house.

All belts can be perforated to your specifications for vacuum or

drainage applications. Hose/Conveyors, Inc. assures accurate hole

punching by using a die cutting machine or precision machined

templates by having this operation in house.

Conveyor Pulleys can be lagged in our shop. Lagging pulleys with rough

top belting, ceramic, flex-lag or slide-lag products enhances the coefficient

of friction between pulley and belt, helping to ensure a positive drive.

Our lagging process includes both cold bonding and/or rivet fastening.

Thermoplastic belts can have the edge capped. Edge capping provides protection

from delaminating and fraying. It also helps prevent introduction of foreign

material (water, food products, and chemicals) into the carcass. The capped

edge is homogenous with the belt construction and is USDA/FDA and 3A Dairy

Industry accepted.

For those applications where conveyor belt skirting or other containment system

wears through the top cover of the belt causing premature belt failure, wear

strips can be the solution. On rubber conveyor belts an extra ¼" thick x 4" wide

strip of rubber is vulcanized to the outer edges of the belt for increased belt life.

Many belts used in manufacturing need to be grooved or beveled. This fabrication

can be performed on regular belts, endless belts, or belts with special laminated

covers (see laminating capabilities).

|

Hose/Conveyors, Inc. die cut capability has a wide range of

applications. From punching holes/perforations in conveyor

belting and specialty machine belting to OEM production die

cut runs. Our capabilities are specially suited for small to

medium run projects.

The materials available include:

|

- Gum rubber

- Conveyor belting

- Sheet rubber

- SBR (Rubber)

- Foam

|

- Gasket materials

- PVC and Thermoplastics

- UHMW

- Teflon

- Etc.

|

Hose/Conveyors, Inc. looks forward to the

opportunity to work with you on your die cutting needs.

For applications that require extra wide belting, Hose/Conveyors, Inc. can splice

together belts making them wider than industry standards. Our custom designed

equipment, manufactured in-house, allows for this process of longitudinally splicing

two or more belts together. Some non-belting applications for this process include

curtains, pit covers, floor mats.

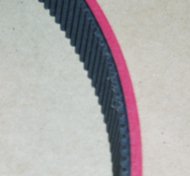

Hose/Conveyors, Inc. offers full lamination services on flat belts,

timing belts, v-belts, poly v-belts, and truly endless belts. Our covers are

permanently bonded with specialty equipment and highly skilled technicians.

| Cover Materials |

Applications |

|

Gum RubberDura ShieldFoam

Sponge RubberNitrileBelting Materials

|

Bottle CappingBottle Manufacturing

Paper TransferBox Manufacturing

Label MachinesSealing Equipment

Converting Equipmentetc.

|

Hose/Conveyors, Inc. can supply urethane timing belts, wire or Kevlar reinforced,

to any length. Cleats, v-guides and wear resistance covers can be installed on

these belts to your specifications.

Hose/Conveyors, Inc. has an expert service department. With our highly trained

technicians and specialty equipment we can handle all your on-site endless belt

needs quickly, efficiently and cleanly.

|